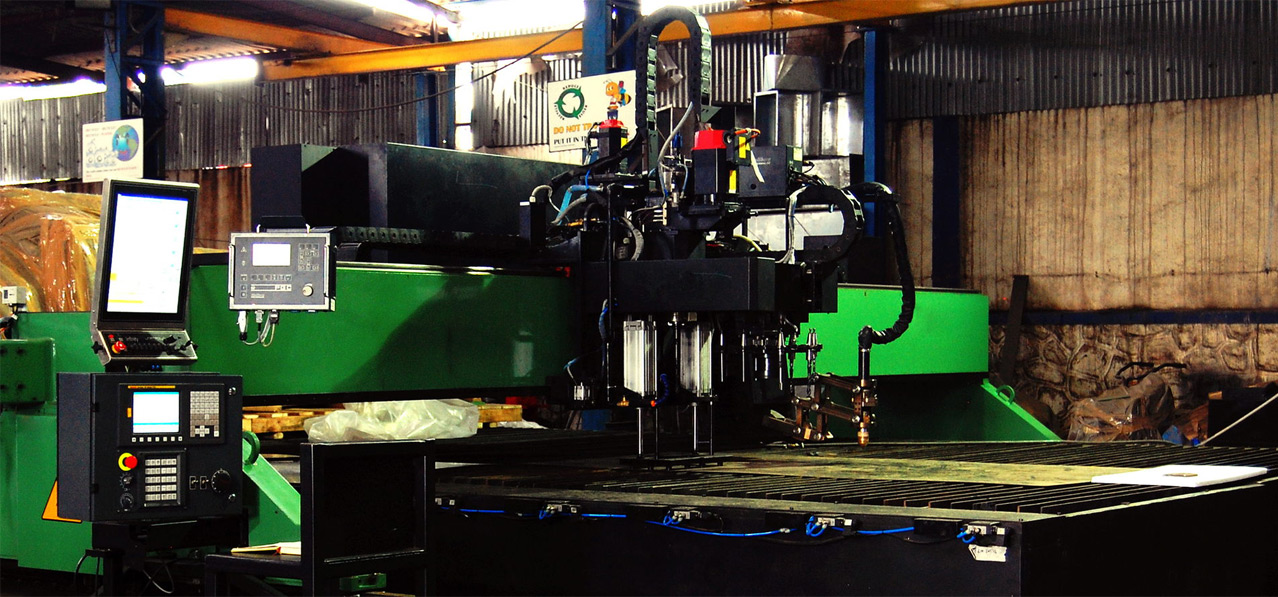

PLATE PROCESSING

PLATE MAESTRO is a plate processing machine that combines drilling, tapping and plasma cutting processes. Eliminates large setup times involved in drilling operation by drilling holes based on CNC program and then cutting components through plasma cutting process.

Features

- Extremely heavy-duty, robust and rigid mechanical structure

- Structure designed to counter deflection and heavy axial loads during drilling operation

- Designed for high acceleration and deceleration required for plasma cutting process

- Easy changeover between drilling and cutting processes

- Designed for high-speed and carbide drills

- Coolant filtration and circulation system

- Magazine for holding different drill and tap tools along with automatic tool changeover mechanism

- Easy to operate GUI ensures less setup time and quicker turnaround time

Technical Specifications

| Process | Gas Cutting, Plasma Cutting, Drillin, Tapping |

|---|---|

| Effective cutting width | 1.5 m to 4 m |

| Effective cutting length | 4 m to 30 m |

| Positioning speed | 0 – 12,000 mm/min |

| Cutting thickness | 0.5 mm – 80 mm MS by plasma cutting 1 mm – 50 mm SS by plasma cutting 6 mm – 150 mm MS by gas cutting |

| Drilling spindle | BT30, BT40, BT50 |

| Drilling capacity | 10 mm to 50 mm |