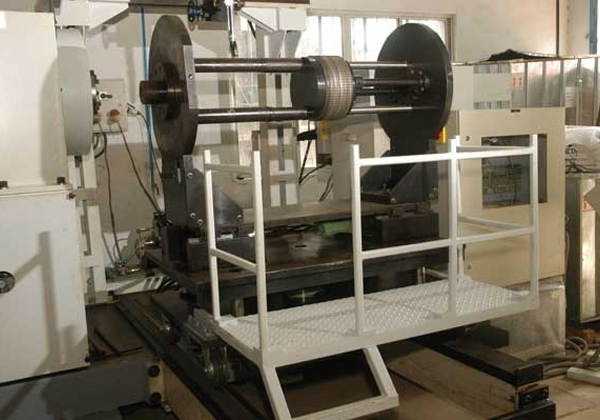

Welding Robotics, Automation & Spm’s

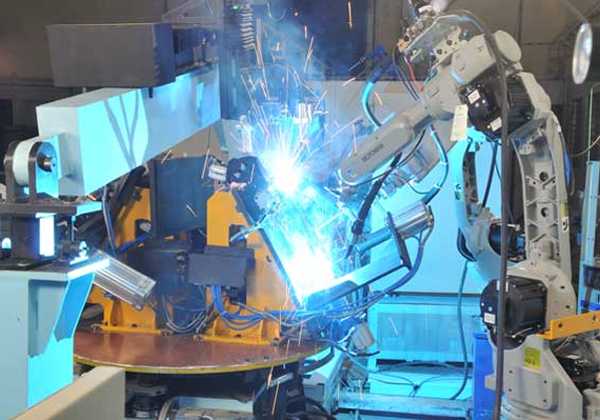

Robotics Welding is the use of mechanized programmable tools (robots), which completely automate a welding process by both performing the weld and handling the part. Processes such as gas metal arc welding, while often automated, are not necessarily equivalent to robot welding, since a human operator sometimes prepares the materials to be welded. Robotics welding is commonly used for resistance spot welding and arc welding in high production applications, such as the automotive industry.

Welding automation uses robots to improve welding by increasing speed, producing quality welds and reducing errors and includes processes like Arc welding, MIG welding, TIG welding, Laser welding, Spot welding and more.

Welding automation is here to stay due to one or many of the following reasons like repetitive and monotonous work, need of the industry to achieve consistent and repeatable quality results, decreasing skill sets across the working manpower, increasing manpower costs.

Why Robotic Welding / Automation / Spm’s ?

The globe has become one small marketplace and it is necessary to become competitive in all industry segments. As volumes of production increase and there is an ongoing need for consistent and repeatable results, automation becomes necessary, whether custom made (SPMs) or robotic cells or fully automated lines.

Applications

Applications include arc welding, spot welding, material handling, gluing, machine tending, palletizing, amongst various others.

GMAW

GTAW

PLASMA